Pvc Pet Pp Pe Pla Transparent Plastic Sheet Film Extruder Making Machine For Plastic Packaging

keywords

PP Sheet Machine

Pet片材生产线

生产塑料包装片材的常用方法有压延,主要用于生产PVC、PVDC等片材;另一种是挤出法,用于生产BOPS、EPS、PET、PP、HIPS等板材。本文所提到的薄板主要是指采用“挤出机- t头-三辊压延装置-卷绕”工艺进行热成型包装产品的薄板生产。

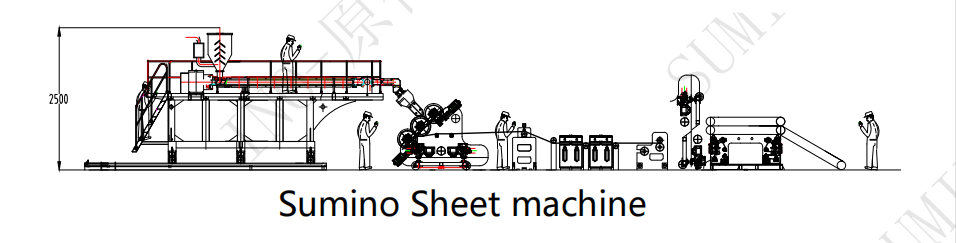

设备预览

安全指导

文具行业

文具行业

吸塑制品行业

吸塑制品行业

广告行业

广告行业

包装行业

包装行业

餐饮业

餐饮业

食品包装行业

食品包装行业

组件行业

组件行业

应用程序

过程原则

卧式三辊薄板生产线:

机组主要由主机、换网机、模具、三层分配器、压片机、输送台、牵引机、切料机或卷料机等组成;

设备布局

我们的物流

我们将为您提供航运公司,让您自己选择合适的航运渠道,我们支持离岸航运方向和在岸航运方向

我们将为您提供航运公司,让您自己选择合适的航运渠道,我们支持离岸航运方向和在岸航运方向

在发货前,我们会给机器涂上防锈油,并覆盖塑料薄膜,然后根据客户的要求包装成木箱或固定在木托盘上或薄膜包装成集装箱。所有机器修好后,我们将使用干燥剂保持容器干燥。

在发货前,我们会给机器涂上防锈油,并覆盖塑料薄膜,然后根据客户的要求包装成木箱或固定在木托盘上或薄膜包装成集装箱。所有机器修好后,我们将使用干燥剂保持容器干燥。

工厂装运

Previous

Pvc Pet Pp Pe Pla Transparent Plastic Sheet Film Extruder Making Machine For Plastic Packaging

High Performance Stone Paper Machinery Direction Orientation (MDO) Extrusion Extruder Extruding line

The PE breathable film extrusion line produces the PE breathable film by mainly using the PE breathable colloidal particles. It adopts the most advanced technologies in the world, among which the extrusion, cast uni-axial stretching technologies play important parts in the whole production.

Multi-layer laminating machine

General Overview of Sumino Machinery Biodegradable Resin PBAT PLA extrusion coating lamination compound machine

Precision Multi-layer Packaging Bidirectional Stretch Film Production Line

It is composed of raw material conveying, extrusion casting, biaxial stretching, traction winding, slitting, process automatic control system, etc. It is used to produce various specifications with excellent mechanical and electrical properties, good cold resistance, gas Biaxially oriented polypropylene (BOPP) film with tightness and dimensional stability. BOPP film is an excellent packaging and insulating material, widely used in food packaging, opaque cold drink packaging, adhesive tape, capacitor film and synthetic paper.

Energy Saving Multi-layer Stretch Film Production Line

The PE breathable film extrusion line produces the PE breathable film by mainly using the PE breathable colloidal particles. It adopts the most advanced technologies in the world, among which the extrusion, cast uni-axial stretching technologies play important parts in the whole production.

Polycarbonate Hollow Roofing Plastic Sheet Machine

Pvc Pet Pp Pe Pla Transparent Plastic Sheet Film Extruder Making Machine For Plastic Packaging

RELATED PRODUCTS