Polycarbonate Hollow Roofing Plastic Sheet Machine

Price

$150,000.00

Brand

SUMINO

MOQ

1

Category

Sheet machine

Contact us

Pvc Pet Pp Pe Pla Transparent Plastic Sheet Film Extruder Making Machine For Plastic Packaging

keywords

PP Sheet Machine

Polycarbonate Hollow Roofing Plastic Sheet Machine

The common methods of producing plastic packaging sheet are calendering, mainly used for the production of PVC, PVDC and other sheets; another is the extrusion method, used for the production of BOPS, EPS, PET, PP, HIPS and other sheets. This paper refers to the sheet mainly refers to the use of "extruder - T-head - three-roller calendering device - winding" process for thermoforming packaging products for the production of sheet.

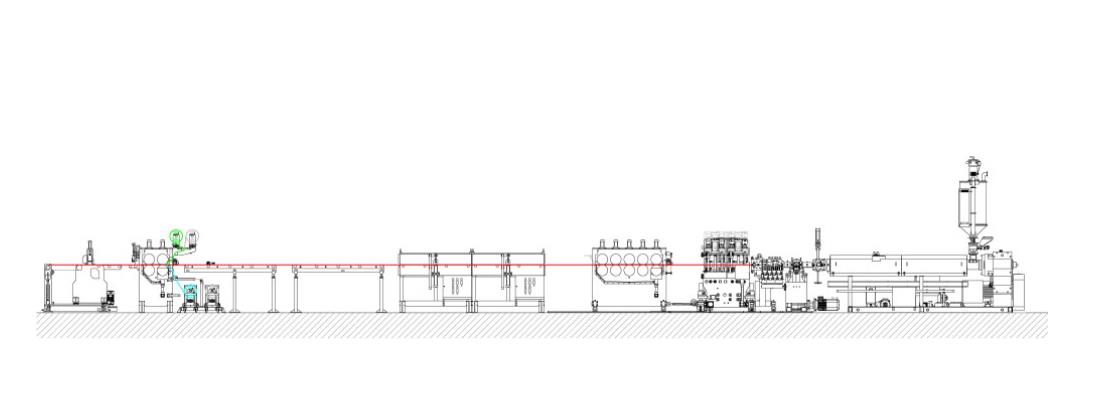

Device Preview

Safety instruction

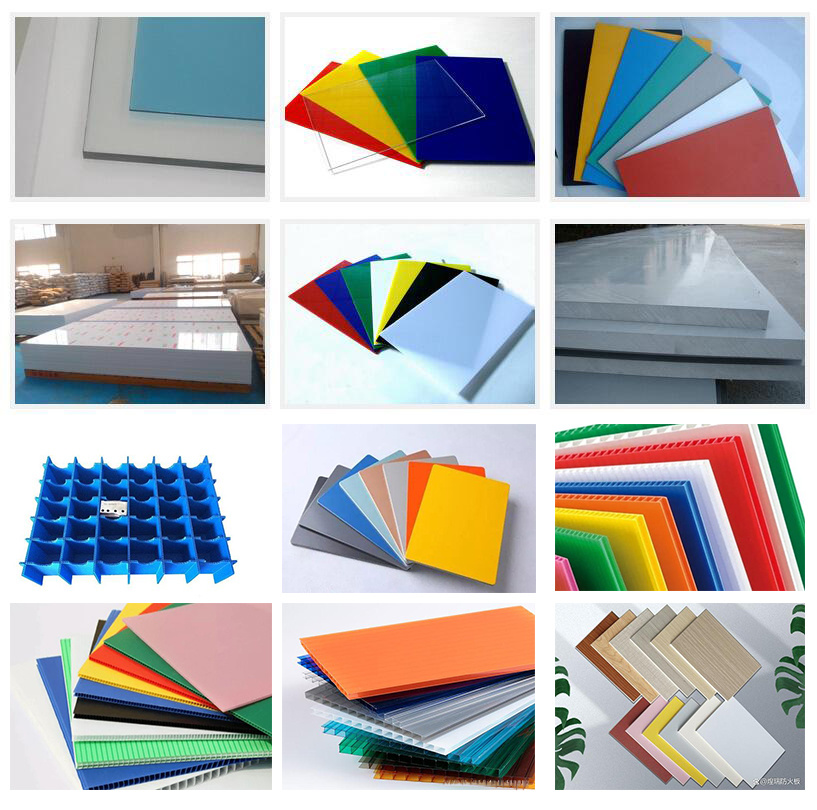

Stationery industry

Stationery industry

Blister goods industry

Blister goods industry

Advertising industry

Advertising industry

Packaging industry

Packaging industry

Catering industry

Catering industry

Food packaging industry

Food packaging industry

Component Industry

Component Industry

Applications

Process Principles

Horizontal three-roll sheet production line:

The unit mainly consists of main machine, screen changer, mold, three-layer distributor, sheet press, conveying table, traction machine, cut-off machine or roll machine and so on;

Reduction box body adopts cast steel parts, gears are made of alloy steel and processed by grinding teeth, each lubrication point in the box adopts forced lubrication, and the lubricating oil is equipped with high-efficiency water-cooling system.

The screw is made of 38CrMOA1A high-quality nitrided steel, which is nitrided and surface sprayed with alloy.

The barrel is made of 38CrMOA1A high-quality nitrided steel, nitrided and sprayed with alloy.

Raw materials can be processed: PP, PE, PS and so on.

Layered structure: AB, ABA.

Equipment Layout

Our logistics

We will provide the shipping company for you to choose the suitable shipping channel by yourself We support offshore shipping direction and onshore shipping direction

We will provide the shipping company for you to choose the suitable shipping channel by yourself We support offshore shipping direction and onshore shipping direction

Before shipment, we will coat the machines with anti-rust oil and cover them with plastic film, then pack them into wooden crates or fix them on wooden pallets or film pack them into containers according to customers' requirements. After fixing all machines, we will use desiccant to keep the container dry.

Before shipment, we will coat the machines with anti-rust oil and cover them with plastic film, then pack them into wooden crates or fix them on wooden pallets or film pack them into containers according to customers' requirements. After fixing all machines, we will use desiccant to keep the container dry.

Factory shipment

Exhibition

COMPANY PROFILE

NANJING SUMINO PRECISION MACHINERY CO. LTD.

NANJING SUMINO PRECISION MACHINERY CO. LTD.

The company is located at No.116 Suyuan Avenue, Jiangning District, Nanjing, adjacent tothe airport, high-speed rail station, and bus terminal, with very convenient transportation.

Sumino Company is a Sino Japanese joint venture and a leading supplier of extrusionsystems and film production lines.At present, Sumino has six production series, includingcasting, stretching, coating, sheet metal, and granulation, with a designed production capacityof 30 equipment/year.

Sumino Company is a Sino Japanese joint venture and a leading supplier of extrusionsystems and film production lines.At present, Sumino has six production series, includingcasting, stretching, coating, sheet metal, and granulation, with a designed production capacityof 30 equipment/year.

In terms of production process, in addition to the five main processes of mechanicalprocessing, welding and coating, final assembly, and electrical testing, Sumino also covers theresearch and development of film forming technology and resin process testing.

In terms of production process, in addition to the five main processes of mechanicalprocessing, welding and coating, final assembly, and electrical testing, Sumino also covers theresearch and development of film forming technology and resin process testing.

The new technological revolution is constantly improving, and we hope to discuss theinnovation and future of thin film manufacturing systems with global consumers.

The new technological revolution is constantly improving, and we hope to discuss theinnovation and future of thin film manufacturing systems with global consumers.

List of factories

Pvc Pet Pp Pe Pla Transparent Plastic Sheet Film Extruder Making Machine For Plastic Packaging

Pvc Pet Pp Pe Pla Transparent Plastic Sheet Film Extruder Making Machine For Plastic Packaging

High Performance Stone Paper Machinery Direction Orientation (MDO) Extrusion Extruder Extruding line

The PE breathable film extrusion line produces the PE breathable film by mainly using the PE breathable colloidal particles. It adopts the most advanced technologies in the world, among which the extrusion, cast uni-axial stretching technologies play important parts in the whole production.

Multi-layer laminating machine

General Overview of Sumino Machinery Biodegradable Resin PBAT PLA extrusion coating lamination compound machine

Precision Multi-layer Packaging Bidirectional Stretch Film Production Line

It is composed of raw material conveying, extrusion casting, biaxial stretching, traction winding, slitting, process automatic control system, etc. It is used to produce various specifications with excellent mechanical and electrical properties, good cold resistance, gas Biaxially oriented polypropylene (BOPP) film with tightness and dimensional stability. BOPP film is an excellent packaging and insulating material, widely used in food packaging, opaque cold drink packaging, adhesive tape, capacitor film and synthetic paper.

Energy Saving Multi-layer Stretch Film Production Line

The PE breathable film extrusion line produces the PE breathable film by mainly using the PE breathable colloidal particles. It adopts the most advanced technologies in the world, among which the extrusion, cast uni-axial stretching technologies play important parts in the whole production.

RELATED PRODUCTS